Surface Coating :

Smooth / Anti-Slip

Colors :

Dark Brown / Black / Gray

Type of Anti-slip Plywood is made using birch plywood as a base material, with a layer of phenolic resin film hot-pressed onto both the top and bottom surfaces. This results in a non-slip, wear-resistant surface that is ideal for flooring applications in transportation and construction where harsh environmental conditions are a concern. The unique textured pattern on the surface enhances its anti-slip and wear-resistant properties, helping to extend the floor's lifespan.

Weather-Resistant Resin-Coated Layers

Both the top and bottom layers of the plywood are coated with a phenolic resin film, and the edges are treated with a waterproof coating. This enhances its resistance to chemicals, sunlight, and rain, making it suitable for use as flooring in challenging environments.

Phenolic Resin Film Coating

Phenolic resin is highly resistant to heat, water, and chemicals, including acids and alkalis. Plywood coated with a phenolic resin film has a smooth, glossy surface that is waterproof, moisture-resistant, weatherproof, and easy to clean with water or steam. It is highly durable and can be reused multiple times. It also resists common acidic and alkaline chemicals. Plywood manufactured according to European technical specifications offers higher durability and a greater rate of reuse.

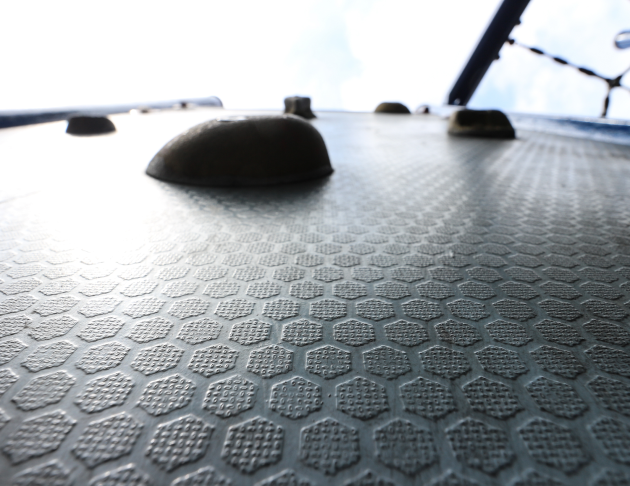

Textured Anti-Slip Surface

The anti-slip birch plywood features a phenolic resin film with a textured surface, enhancing its slip-resistant and wear-resistant properties. The textured pattern not only provides functionality but also adds a decorative element. Different film densities and surface patterns offer varying slip resistance levels, making the plywood suitable for areas requiring anti-slip and wear-resistant surfaces, such as recreational flooring, stage flooring, transport containers, vehicle beds, and ship decks.

European birch plywood, particularly Finnish plywood, is widely used in the construction and transportation industries due to its excellent load-bearing capacity and stability. In construction, it is often used as formwork for concrete pouring. In the transportation sector, it serves as flooring material for trailers, trucks, ships, containers, warehouses, loading platforms, temporary stage floors, playgrounds, sports fields, and ship decks and roofs.

Construction plywood is specifically designed for use in building sites, either as formwork for shaping concrete pours or as scaffold boards during building construction.